Industrial Augmented Reality (AR) is a technology that complements existing manufacturing processes and enables companies to improve efficiency and increase quality. AR enables companies to cut costs, reduce time to market, and build safer products.

With applications in the industrial and manufacturing sector including logistics, manufacturing floors, maintenance, upskilling, and training, organizations that have specific processes or require complex product components often find that implementing industrial AR optimizes operations across the entire product development cycle.

Industrial AR takes product development to the next level by enabling designers to see how products will look and work in real-life conditions. This gives designers invaluable insights into what consumers want, allowing them to make modifications before the physical prototype is complete. This in turn reduces the costs of physical prototyping, saving time and money. Industrial engineers can also use the technology to plan and optimize processes that can help to ensure that your manufacturing output is consistently high quality.

AR technology is set to change the face of the industrial and manufacturing industries, with PTC’s study on AR finding that nearly 75% of industrial organizations had some form of AR integration at the end of 2019. With such widespread adoption of the technology, all industrial and manufacturing enterprises must consider integrating enterprise AR solutions into their operations. Not doing so will mean entities risk being left behind.

Let’s chat

Not sure where to start? Book a free strategy call with us to get started! No strings attached.

Application of AR in Logistics and Manufacturing Floor

Logistics

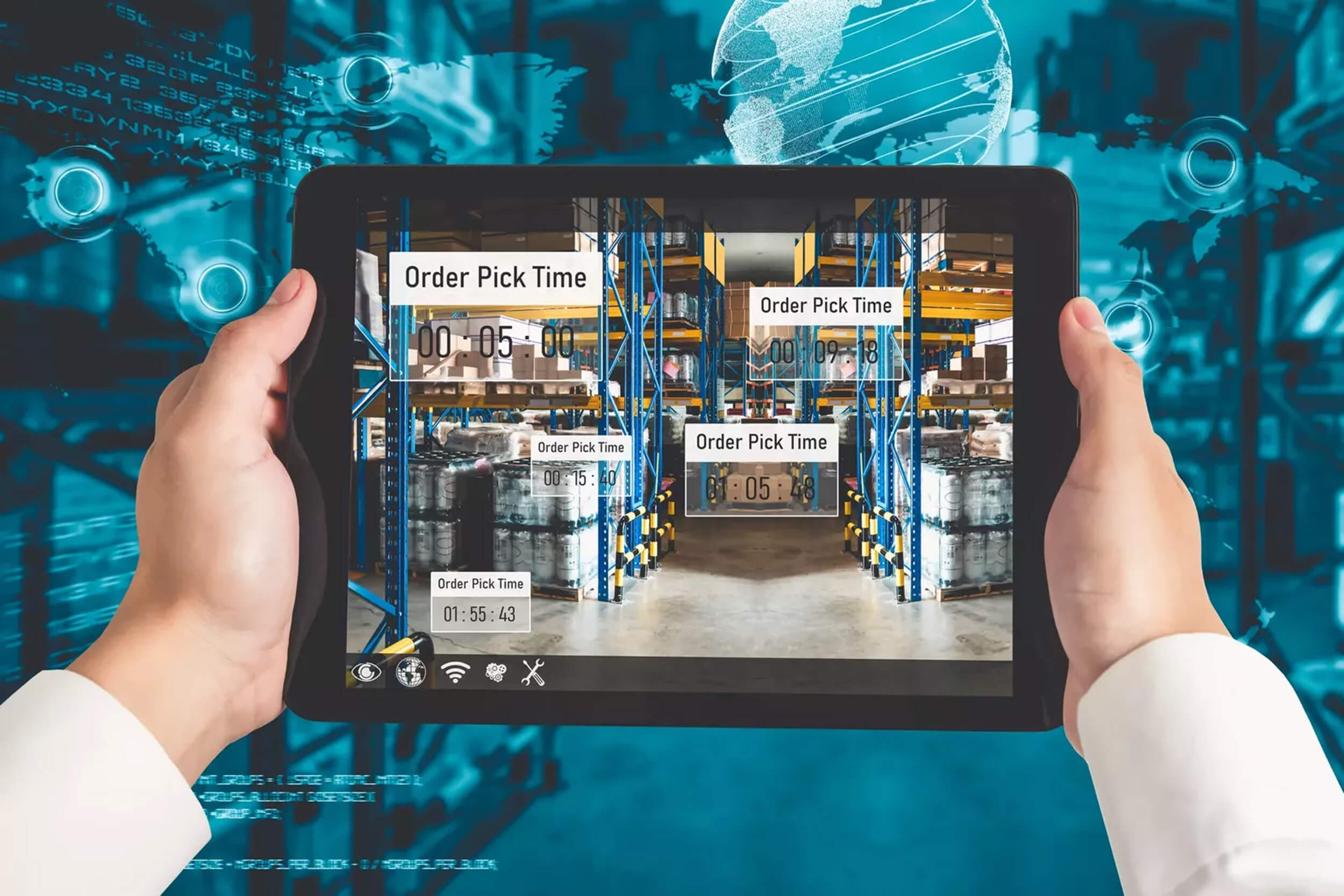

Managing orders and organizing warehouses is a time-consuming process. Workers have to verify information, locate and scan the selected products, deliver them to the dispatching area, and then sign off on the order. This process makes logistics prone to error.

Industrial augmented reality enables workers to be much more precise and productive. It enables them to access a connected system that automatically guides them towards the correct products. Mobile AR systems such as head-mounted displays enable object recognition, barcode reading, and seamless information integration – all in a worker’s field of vision. All that’s left for them to do is get and drop off the product.

Industrial AR is extremely effective, decreasing picking errors by as much as 40%. This translates to millions of saved dollars in the long run. In fact, logistic giant DHL has already latched onto the value of industrial AR and has allocated a massive $300 million investment in the technology.

Augmented reality allows workers to be more precise and do away with cumbersome written lists and instructions.

Manufacturing Floor

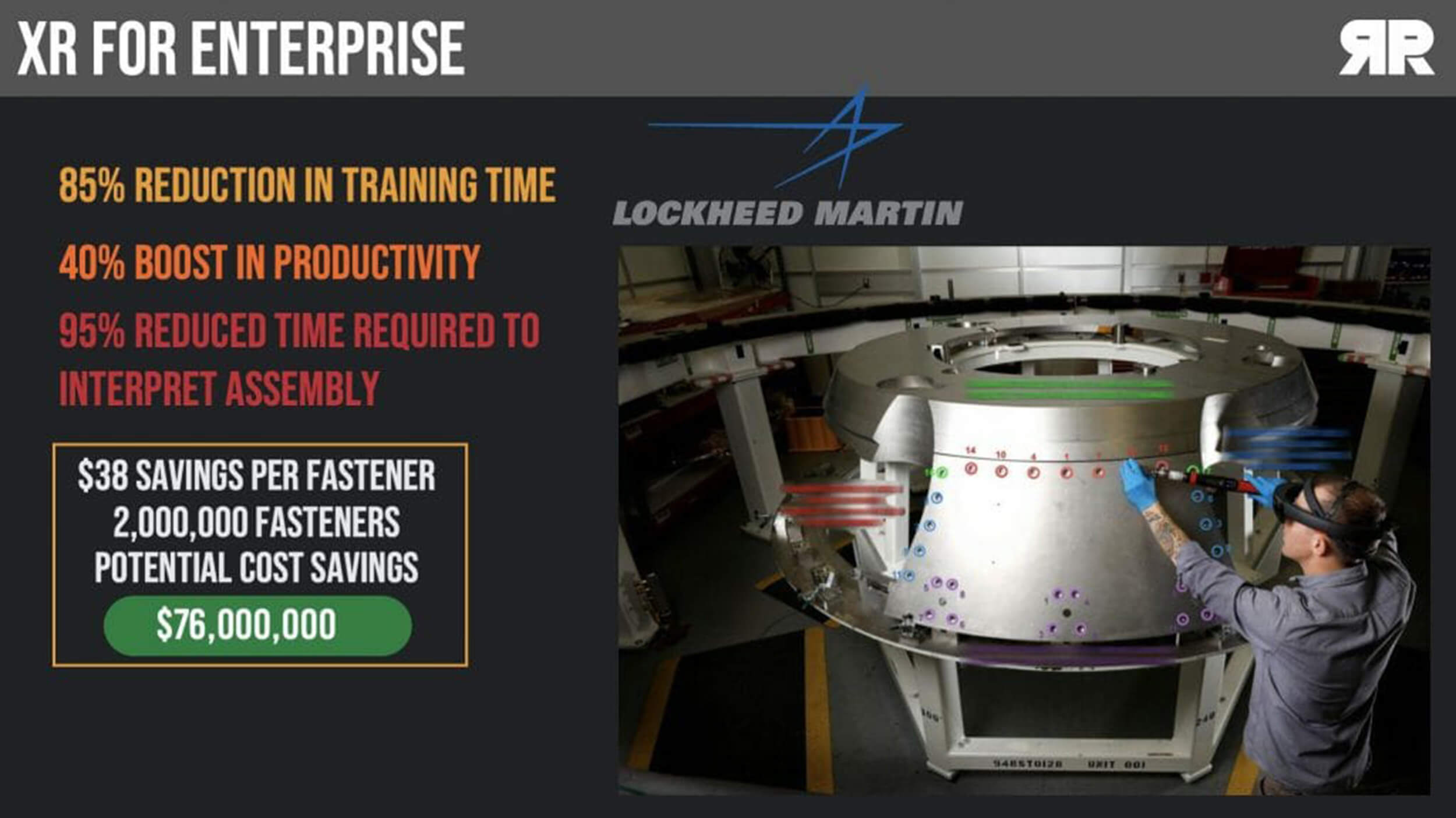

Industrial AR promises to increase manufacturing floor efficiencies. It enables workers to quickly be trained in new processes and assemblies right on the shop floor. These operational instructions are presented directly in their line of sight, enabling them to process information while leaving their hands free to tackle other tasks simultaneously.

This ability of AR technology to immerse users is perhaps its most potent feature. Manufacturing personnel can access technical documents, stream instructional videos, and receive 3D guidance all while productivity continues.

Increasing Efficiency in Maintenance Using AR

Industrial augmented reality is a powerful tool that can significantly improve service times and accuracy for maintenance providers. At a basic level, it enables workers to see hardware issues and required servicing. In addition, AR technology can display operation times, maintenance history, potential future breakpoints, and much more.

Industrial AR also allows for more proactive maintenance. Service personnel equipped with mobile AR devices can automatically scan hardware whenever they hit the factory floor. This identifies early-stage maintenance requirements, eliminating the need for bigger and more costly interventions later down the line.

Faster and more efficient maintenance using AR has been ably demonstrated by General Electric. GE reported a study where a technician had to wire a wind turbine control panel using physical work instructions vs instructions delivered via an AR headset. The technician displayed a 34% efficiency improvement in performance when using the AR headset.

Keep up to date

Sign up to our newsletter for exclusive updates and content, delivered directly to your inbox.

Better Upskilling and Training With AR

Upskilling

Upskilling is integrating smart technology with production workers and their processes. AR performs this integration smoother than any other technology due to its rich immersive capabilities.

Mobile AR headsets and other devices have such smooth integration due to the ability of the technology to overlay information. By displaying useful information in the form of images, graphics, and text, workers can easily learn new processes, operations, and equipment operations. This translates into greater productivity and savings.

Training

Training industrial workers is a time and resource-consuming process. As they are new to the job, they are naturally unfamiliar with the necessary protocols, equipment operating procedures, and other standard factory floor conventions. Not only does this lead to production inefficiencies, but also raises safety issues. Expense is another consideration when training new workers, as it often involves having them shadow senior staff in order to learn.

Industrial AR solves many of these problems. It can instantly deliver useful information and procedures so that trainees can learn as they go about their duties. The technology also offers a more uniform and complete transfer of knowledge and methodologies, rendering more effective training initiatives.

It is not only more effective but more cost-efficient. By being able to guide trainees through every step and process, the need for expensive human instructors is eliminated. This also frees up manpower to focus on other tasks.

AR also handles the safety issues that usually accompany traditional training. It allows trainees to get hands-on experience with simulated equipment. Naturally, this results in a safer training process while increasing efficiency – the equipment that trainees would have otherwise practiced on is instead freed up to be used for production. Industrial AR training is also replicable. This means that you only have to develop the training process once and it can be rolled out for all future training sessions.

Industrial AR Is Ready to Revolutionize

Augmented reality is set to revolutionize many industries, but perhaps none more so than the industrial and manufacturing sectors. The technology increases efficiencies across a range of applications, including logistics, manufacturing floors, maintenance, upskilling, and training.

Finding an AR solution that is right for your organization is essential and one of the most important steps in the decision-making process to adopt AR for your industrial application. You can’t afford to be unprepared and given the rate of adoption and need to deploy quickly, you need a partner that can help deliver value quickly and has experience in fostering innovation – that partner is Rock Paper Reality.

We’re a veteran Augmented Reality agency that helps companies from startup to Fortune 500s develop best-in-class AR content, WebAR Solutions and understands the specific needs of the industrial and manufacturing sectors. Our team ofconsultants are from top-tier consulting firms and will find the right AR solution for your use case.

Want to learn more? Rock Paper Reality is ready to transform your industrial project with AR.